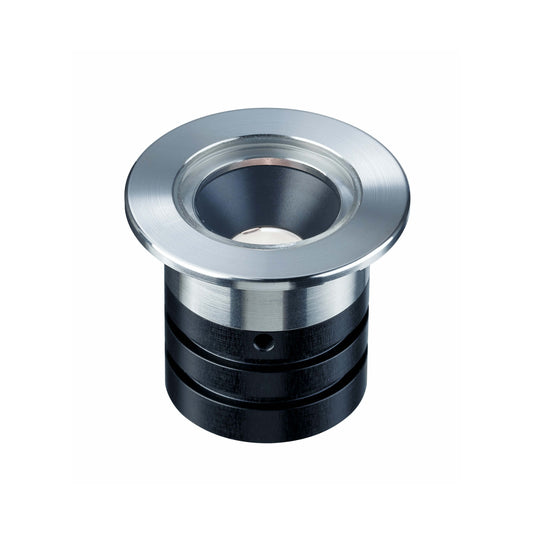

LD56T IP68 ground-recessed uplight with fixed tilt LED

A small, very tough, low glare fitting with the LED set at a 6º tilt which can be used for uplighting, wall washing or step lighting. IP68. Available with longer leads if required

Product Info

The LD56T packs a lot of features into a very compact product with a recess depth of just 42mm. The LED is angled at 6º to focus the light onto and up a wall or column with fantastic beam shape and spread. Deep recessed optics reduce glare with an optional glare shield available to further improve visual comfort.

Rated IP68, the LD56T is incredibly versatile and has been used in projects all over the world in various applications, including as a downlight. It is a very tough, high quality fitting, with a minimal aesthetic.

We offer a range of optional longer lead lengths which allow longer cable runs back to the driver location for ease of installation or weather-proofing reasons.

Technical Info

Technical Info

A small, tough, low glare fitting which can be used for uplighting, wall washing or step lighting. It’s sealed to IP68 so can be used outside and the integral anti-wicking barrier increases protection against water ingress due to incorrect IP rated cable connections.

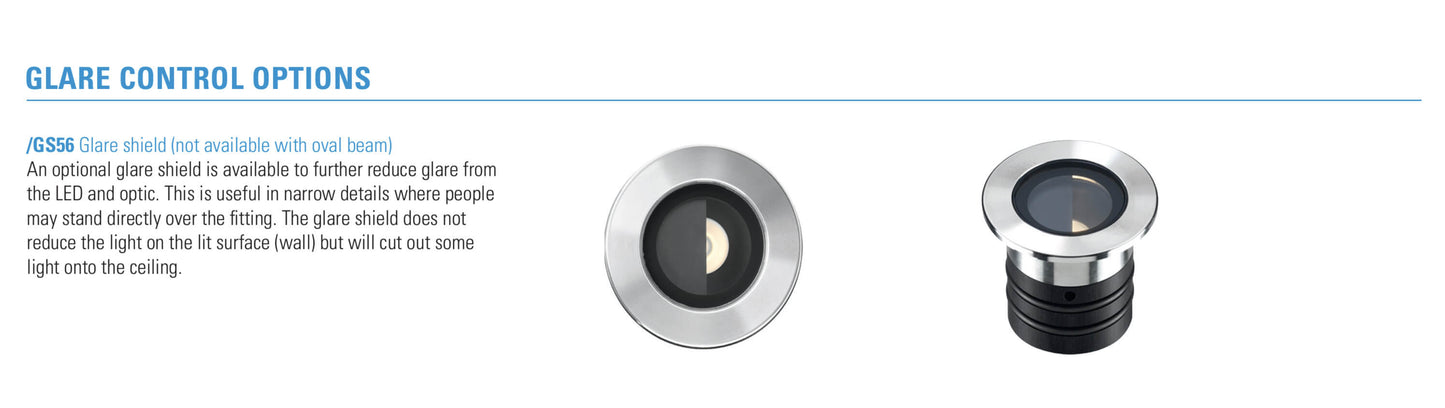

An optional glare shield is now available to further reduce glare from the LED and optic. This is really only necessary in narrow details where people are going to be directly over the fitting. This does not reduce the light on the lit surface (wall) but will cut out some light onto the ceiling.

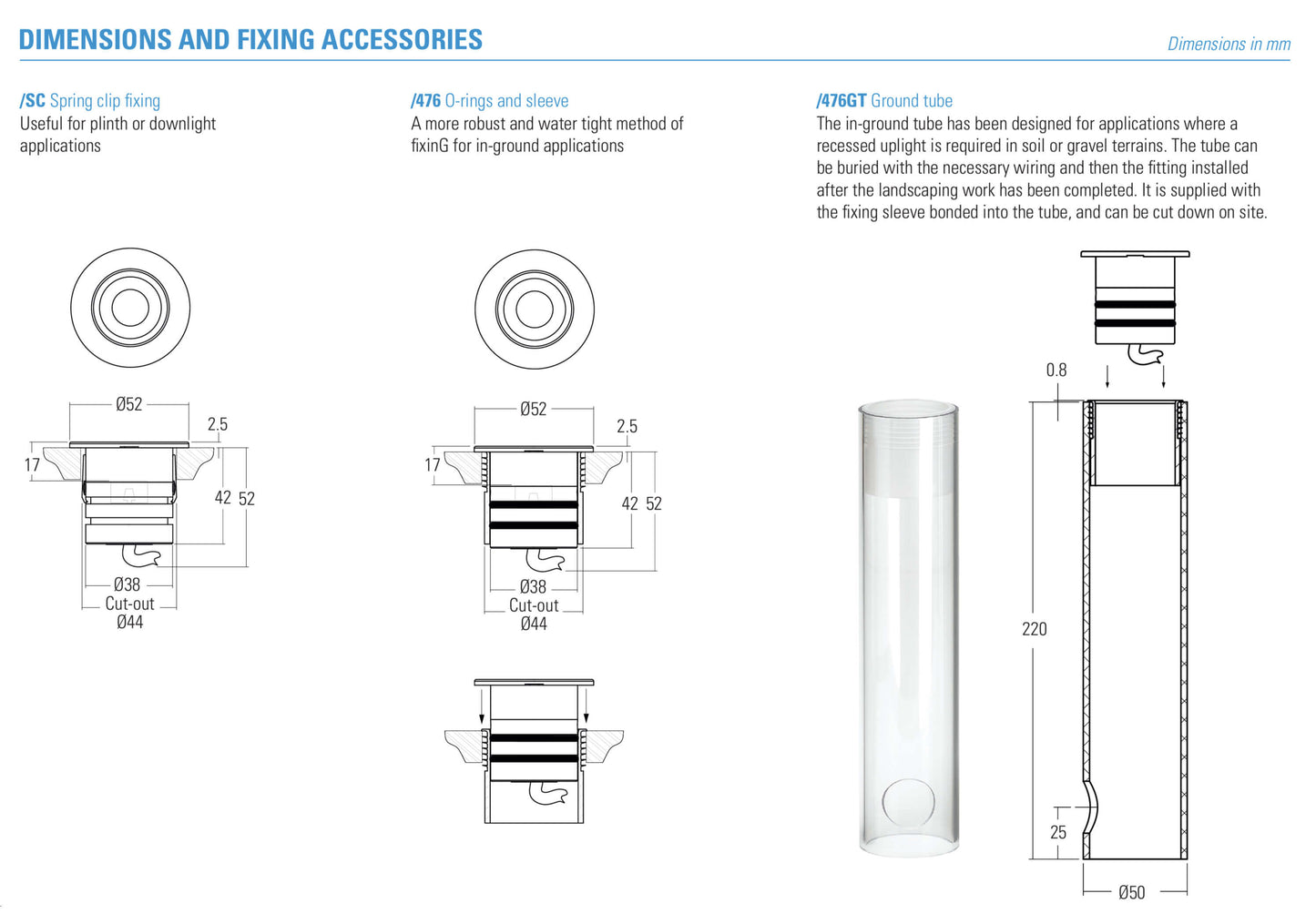

See the product spec sheet in Resources for fixing options. Comes pre-wired with a 2 core 100mm cable.

The higher the current (mA) the fitting is run at the more light you will get.

A 90,000 life expectancy and a 3 Year fitting warranty.

Driver options

The LD56 is a constant current fitting which requires a driver to run it, drivers can run multiple fittings but fittings must be wired in series. With an appropriate driver the fitting is dimmable via 0-10V, DALI and Mains leading/trailing edge or non-dim. Please select dimming type on options tab above and that will take you through to a page detailing how many fittings you can run per driver.

Installation Notes

The fittings should be wired in series and the cable run between the driver and the fitting should not exceed 10m. The driver should be located somewhere discrete, allowing air movement and be accessible for maintenance